[BLOG] How to Choose a Table Base

There are hundreds of table bases to choose from each with their own specific features and applications. Here is a comprehensive look at all the features and specs of table bases that you need to know about before choosing a table base.

Required Height

Table bases come in a variety of heights, and some can also be custom cut to your specified height. The most common table base heights are:

- Desk or Office Height = 28""

- Counter Top Height = 34"" to 36""

- Bar or Pub Height = 40"" to 44""

Desk or office height table bases are commonly used in office and educational applications but are also used on kitchen tables. Desk or office height tables are what you would think of as traditional or standard height tables.

Counter top height table bases are most commonly used in kitchens for tables, kitchen islands and peninsulas, breakfast nooks, or counter top overhangs. However, they can also be used on standing work stations.

Bar or pub height table bases are used (as you probably could guess) on bar tables, bar overhangs and bar extensions.

Montclair Stainless Steel Bolt Down Table Base

Static or Mobile

Another factor you will need to decide on is if you want your table to be able to be moved or if you want your table to be attached to the floor.

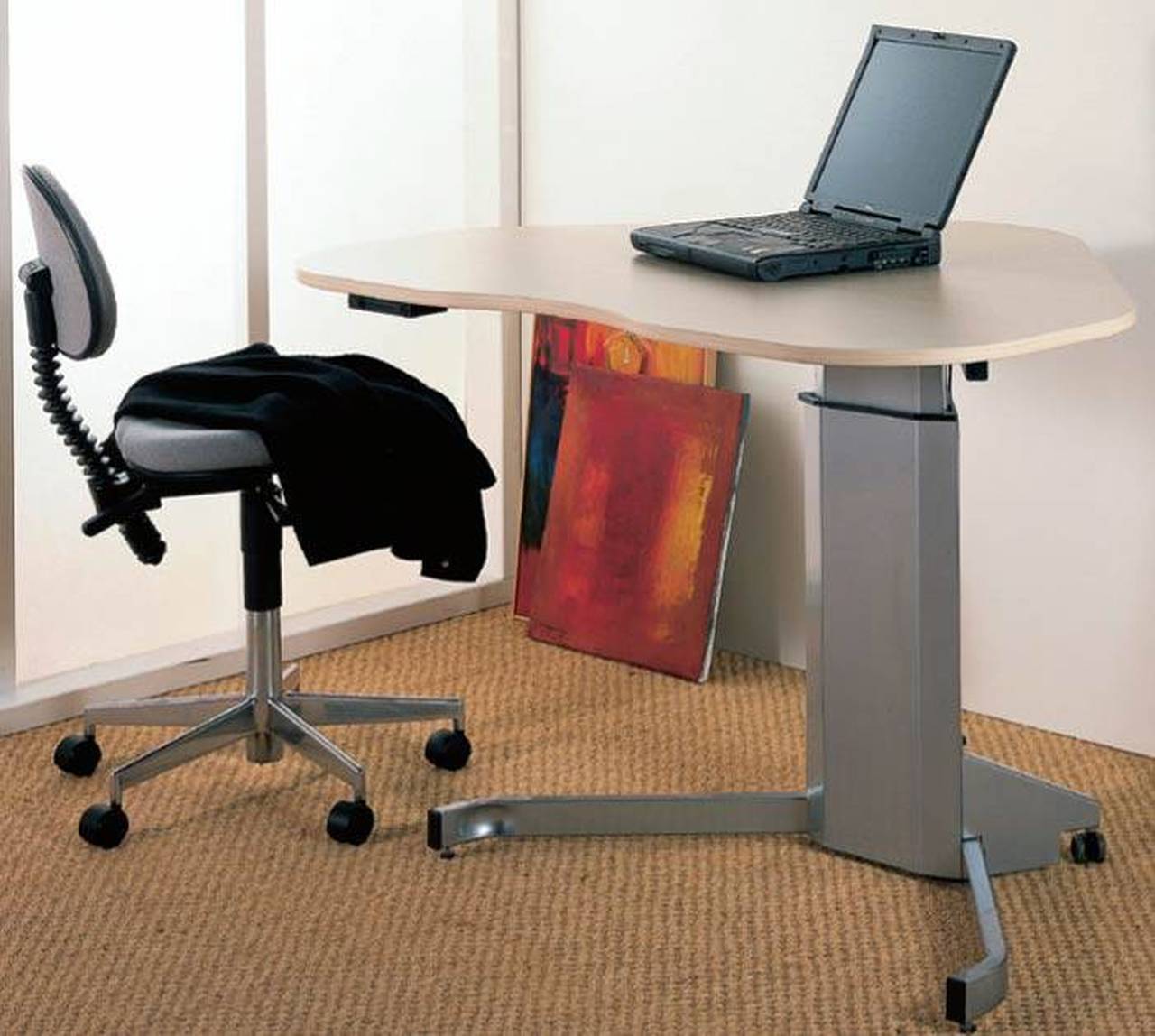

Most tables will use standard table bases and will not be mounted to the floor. In some cases, as in some restaurant tables, or if you are installing a counter overhang, you may want to have the table base bolted to the floor for additional stability and security. In addition, you will need to decide if you want your table base to be on wheels. There are quite a few table bases that come with casters in case you need extra mobility.

Base Type

Table bases come in a number of different base or foot types. Some common examples of base types are disc, square, rectangle, tripod, drum, X-Base, C-Base, H-Base and T-Base.

| C-Base | Disc | Drum |

| H-Base | Rectangular | Square |

| T-Base | Tripod | X-Base |

Number of Bases

The number of table bases that you use for your table will depend on two factors: table dimensions and base type. If your table is 8' x 4', you are not going to be able to use a single base. Even the largest table bases can only handle so much overhang. The base manufacturer should specify the maximum size table for that particular base. There are several base types that require at the minimum two bases. This is because of how the bases are designed. C-bases, H-bases and T-bases need at least two bases in order to be stable.

Base Spread

The base spread will determine how stable your base is and will define the maximum dimensions of your table. In general, the smaller the base spread, the smaller the table top. You would not want to use a base with a 6"" base spread on a 48"" table, at least not if you want your table to be standing upright... Incidentally, base spreads generally do not come that small. Bases will usually come with a base spread of 16"" up to 60"" for some really large bases.

Load Capacity

When choosing a table base you must also consider the load capacity. A base will have a static vertical load rating. This rating determines how much weight the base can handle. You will need to figure out the weight of your table and also the weight of anything you may be placing on the table such as kitchen appliances, office equipment or electronics. If you do not have access to the specs of your table top, as in a custom-built table top, you can use this table top and counter top weight calculator to estimate the weight. *Note: Load capacity is based on static vertical load. This load rating is only taking into account downward force. I have worked with people who attempted to move their table by pushing it. In the case of moving tables with heavy table tops (some hardwoods, granite, stone, etc.), or attempting to move the table while there are still heavy objects on the table, you will create a horizontal force and load that may cause the table base mount to loosen, warp, or even break.

Adjustment Capability

Do you need your table to be adjustable? Examples being: You need your desk to adjust between desk height and standing height, you need your restaurant table to adjust between seating height and bar height, or you need your cafe table to be ADA compliant.

Style

Table bases come in a number of styles. Here are some style examples...

Acanthus |

Antique |

Bolt Down |

|

Modern |

Traditional |

Arched vs. Flat

This is just a style preference, and there is no difference in function between the two.

| Flat | Arched |

Column Diameter

The column diameter of most table bases range between 1" and 6". If you are looking for even a wider diameter than 6"", you will want to check out drum bases. Bases may also have one column or multiple columns, up to four, but possibly more. There is not much difference in load ratings for single column bases. It is basically an aesthetic choice. Bases with more columns will generally have a higher load rating.

Mounting Plate Type

Mounting plates will most often come in two different types: square mounting plates and X-shaped mounting plates. There is no real difference from a functionality or quality standpoint between a square plate and an X-plate.

You can also get a special flip-top mounting plate that allows you to ""flip"" the table top into a vertical position for easy storage. Keep in mind that with flip-top tables your table diameter must be LESS than double the height of your table base column. If you are planning on mounting your base to a glass top, make sure your chosen base is designed for glass top applications. The base will have a special glass adapter that attaches to the column and then the glass top can be glued to the adapter using special adhesive.

Mounting Plate Size

The size of mounting plates range from around 3"" all the way up to around 24"" in diameter. Wider mounting plates will provide more table stability, generally speaking. In some cases, bases will have multiple columns with smaller mounting plates vs. having one column with a larger mounting plate. Make sure to keep in mind the size of your table and follow the base specs when choosing a mounting plate size.

Construction

There are three ways that table bases are constructed and manufactured. They will either have a welded assembly, thru-bolt assembly, or a combination of the two. The bases will either be thru-bolted or welded where the column attaches to the base and also where the column attaches to the mounting plate. A welded base, such as a cast iron table base, comes pre-assembled and ready to use. A base that requires bolted assembly will be shipped un-assembled and can be taken apart if needed.

Finish

The finish of your table base is usually what most people consider first when they are buying a table base. There are dozens of finishes available, not to mention if you wanted to add a custom finish yourself, such as painting the base. We do not recommend painting your base as most bases are usually metal and they are finished with a special powder-coating. You can however paint your base if you desire, just make sure you use a paint that is designed for metal applications.

The most common finishes are: black, chrome and brushed steel. Custom finishes come in a wide array, ranging from white to brass to even champagne. There are also wood-metal combination finishes as well as stainless steel finishes. These two should really be listed under ""Material"", but some people list them under finishes.

Material

Table bases will be made from several different materials. The most common are stainless steel, steel, iron, aluminum and wood.

Stainless steel bases are great for restaurants, kitchens and outdoor tables. This is because stainless steel is rust resistant. If your table base might be coming in contact with liquids on a regular basis, you may want to go with stainless steel. If you will be working with or near food, check out bases made of 304 "food grade" stainless steel. 304 grade is the most common grade of stainless steel and should be used in food preparation and dining applications. It is used because it is resistant to the corrosion caused by the acids found in fruits, vegetables and meat, and is very easy to sanitize.

Aluminum is a great choice for a base if you would like a lighter base, as aluminum is not a very heavy metal but is still extremely durable.

Levelers

Some bases will come with leveler feet and some will not. You will need to decide if you need them or not. Levelers will be needed in situations where there may be be uneven floor surfaces, such as in older buildings or outdoor surfaces. Levelers will usually give you an adjustment of 1/4" to 1".

Base Accessories

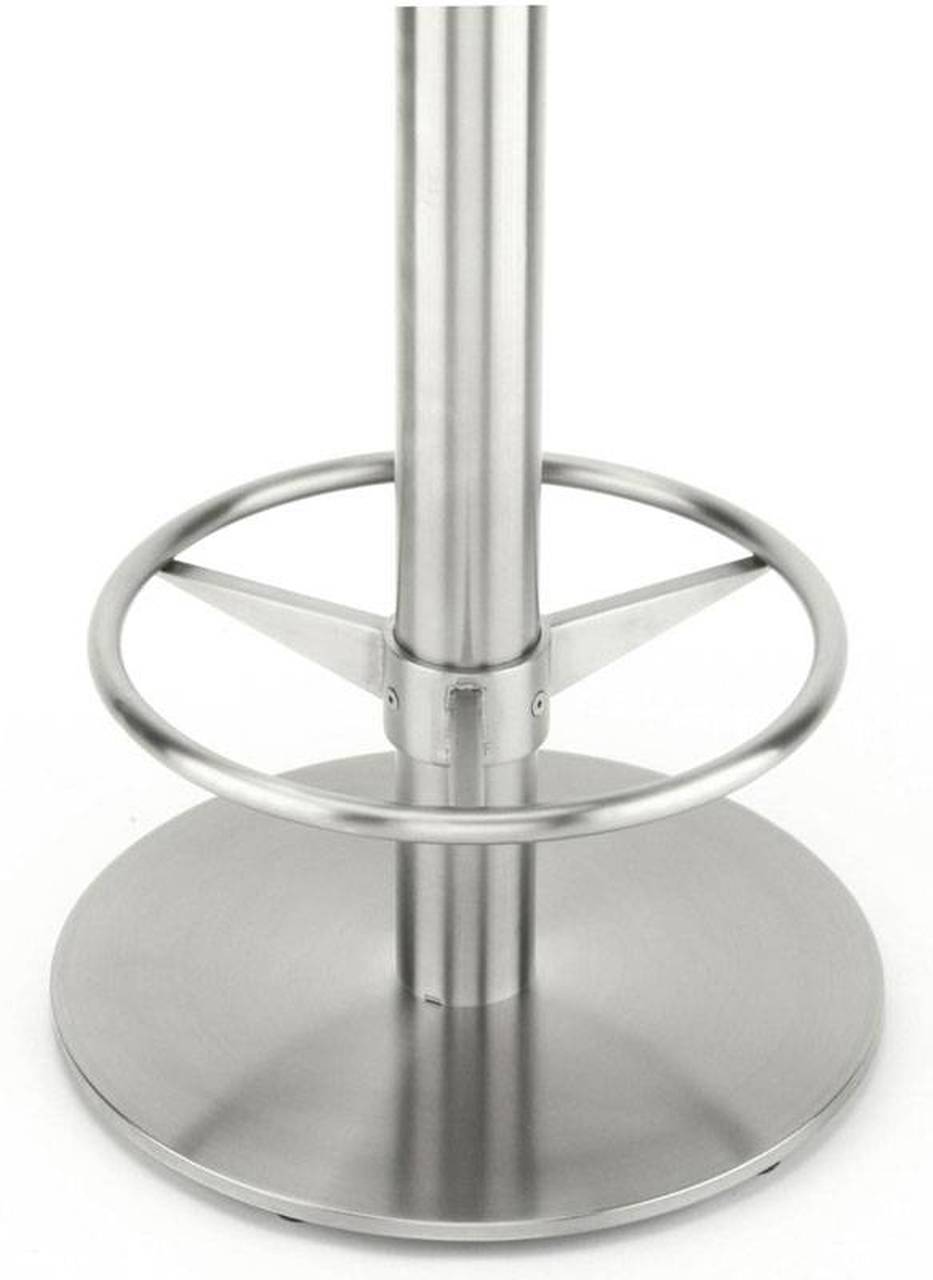

The last thing you will have to decide is if you want any base accessories. Base accessories are: footrings, anti-sag support bars, modesty panels and wire management systems. Footrings are great for bar tables. They allow you to rest your feet on the base so that they are not left dangling from a bar stool. Modesty panels and wire management systems have obvious uses in office settings."

| Foot Ring | Modesty Panel with Wire Management |